A Comprehensive Guide to Applying Foam Control Solutions in Your Operations

Efficient foam control is a vital facet of functional efficiency that frequently goes overlooked. Understanding the complexities of foam generation can significantly influence both performance and item top quality. By examining crucial elements such as application compatibility and workers training, organizations can maximize their foam monitoring initiatives.

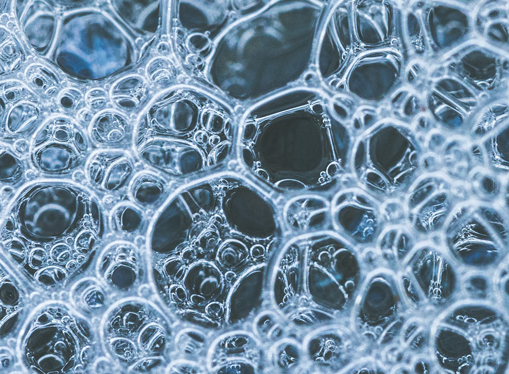

Comprehending Foam Obstacles

Foam difficulties are a considerable concern across different sectors, influencing functional efficiency and item top quality. The development of too much foam can impede procedures such as mixing, transportation, and storage, leading to boosted downtime and waste. In fields like food and drink, drugs, and petrochemicals, foam can hinder production lines, triggering product inconsistencies and contamination threats.

Additionally, foam can obstruct tools functionality, bring about expensive fixings and maintenance. In wastewater therapy, foam can interfere with clarifier operations, resulting in reduced therapy performance and governing conformity concerns.

Comprehending the underlying sources of foam generation is crucial for effective monitoring. Variables such as surfactants, temperature level fluctuations, and agitation degrees can all add to foam manufacturing. Identifying these elements allows markets to apply targeted methods that reduce foam formation while keeping product integrity.

Kinds Of Foam Control Solutions

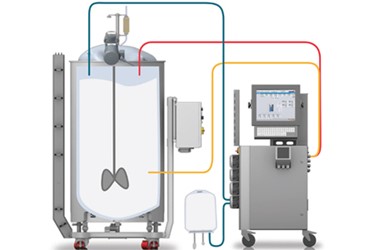

Mechanical solutions involve using devices such as foam skimmers or defoamers. These devices physically remove foam from the surface of liquids, consequently stopping overflow and maintaining optimum levels in reactors and containers. Chemical options, on the various other hand, consist of the application of defoaming agents-- substances that interrupt the foam framework, bring about its collapse. These agents can be silicone-based, natural, or liquid, each offering distinct benefits relying on the application environment.

Finally, functional approaches focus on procedure modifications. This may entail customizing equipment parameters, such as temperature and stress, or transforming the circulation prices of liquids to minimize foam generation. Furthermore, carrying out great housekeeping methods can likewise alleviate foam development by lowering pollutants that contribute to foam stability.

Picking the suitable foam control option includes examining the certain requirements of the operation, including the kind of procedure, the features of the products involved, and security factors to consider.

Picking the Right Products

Choosing the appropriate foam control products calls for a detailed understanding of the certain application and its special difficulties. Factors such as the kind of foam, the atmosphere in which it occurs, and the preferred result all play pivotal duties in product choice. Foam Control. In sectors like food processing, it is crucial to choose food-grade defoamers that comply with safety policies while effectively taking care of foam.

Furthermore, think about the viscosity of the liquid where the foam problem exists. Some products are created for low-viscosity applications, while others are customized for thicker liquids. Compatibility with existing processes is an additional crucial element; the picked foam control agents should integrate perfectly without interfering with overall procedures.

An additional crucial variable is the method of application. Some items might require dilution, while others can be applied directly. Analyzing the convenience of use and the called for dosage can try this website provide understandings into the item's performance and cost-effectiveness.

Execution Approaches

Successful implementation strategies for foam control remedies need a systematic strategy that lines up item selection with functional needs. The primary step includes a detailed evaluation of the processes where foam occurs, determining specific locations that necessitate intervention. By engaging cross-functional groups, including design, top quality, and production guarantee, organizations can gather insights that notify the selection of one of the most efficient foam control items.

Following, it is essential to establish clear goals for foam decrease, guaranteeing that these goals are attainable and measurable. This may include specifying acceptable foam degrees and the timelines for execution. Educating workers on the buildings and application approaches of chosen foam control agents is equally vital, as correct usage is essential for optimal results.

In addition, integrating foam control remedies into existing workflows calls for cautious planning. Inevitably, a well-structured strategy will certainly boost functional effectiveness while effectively taking care of foam-related difficulties.

Surveillance and Examining Effectiveness

Tracking and evaluating the efficiency of foam control services is important for guaranteeing that executed approaches generate the desired results. This procedure involves organized information collection and analysis to examine the performance of foam control agents and techniques. Trick efficiency signs (KPIs) must be established before execution, enabling a clear baseline versus which to gauge progression.

Reviewing performance additionally calls for regular testimonials of foam control treatments and agent efficiency. This can be achieved with sampling and testing, allowing drivers to figure out if existing services are fulfilling functional requirements. It is essential to obtain responses from group members who interact with find more information these systems daily, as their understandings can reveal operational nuances that measurable information may ignore.

Inevitably, a structured tracking and evaluation structure aids determine needed modifications, making sure that foam control solutions stay reliable, cost-effective, and lined up with business goals.

Final Thought

In final thought, reliable foam control options are crucial for optimizing functional effectiveness and keeping item quality. An extensive understanding of foam difficulties, combined with the option of proper items and execution techniques, promotes the effective monitoring of foam generation.

Carrying out great housekeeping techniques can additionally minimize foam formation by lowering contaminants that add to foam security.

Picking the appropriate foam control items calls for a complete understanding of the specific application and its unique difficulties (Foam Control).Effective implementation methods for foam control remedies need a methodical technique that aligns product selection with operational requirements.In final thought, reliable foam control services are necessary for maximizing functional performance and maintaining product top quality. An extensive understanding of foam challenges, incorporated with the selection of proper see here items and execution approaches, helps with the effective monitoring of foam generation